Fiber-optic networks are simple and straightforward in their basic principles.

However, the different types of networks and network hardware can make your head spin.

Take fiber optic connectors, for instance. How different can a LC connector be from a SC fiber connector?

The answer is – quite different, both in terms of design and performance.

And these two types are just the beginning! We’re going to break down all you need to know about the different fiber optic connector types.

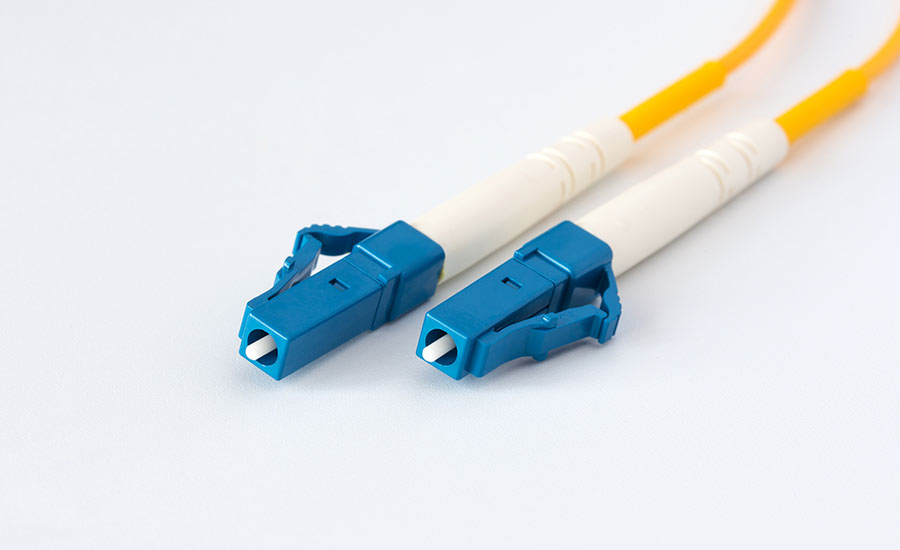

Fiber Connector Type #1: LC Connector

No one knows for sure what the “LC” in LC Connector stands for.

According to some, it means Lucent Connector, as it was developed by the now-defunct Lucent Technologies.

According to others, it means Little Connector or Local Connector.

Something that all fiber-optic specialists seem to agree on, however, is that the LC connector is undoubtedly one of the most popular fiber optic connector types on the market.

The main advantage of the LC connector is its small form-factor, which makes it the go-to connector type for busy networks.

At the same time, it features a snap coupling latch, which makes connecting and disconnecting the cables easy.

The key features of the LC connector are:

- Ferrule size and material: 1.5 mm, ceramic

- Interface standard: IEC 61754-13

- Mating cycles: 500

The LC connector is one of the most cost-effective and user-friendly fiber-optic network solutions. Combined with its compact size, that makes it an excellent choice for populated networks such as data centers.

Fiber Connector Type #2: SC Fiber Connector

The SC fiber connector is an old and familiar staple in the world of fiber-optic cable connectors.

Developed in the 1980s by the Japanese Nippon Telegraph and Telephone corporation, it was one of the first standardized connector types.

The SC fiber connector is somewhat of a predecessor to the LC connector, as the two share the same basic design – a ceramic ferrule and a snap coupling latch.

And while the LC is smaller and more advanced in terms of performance, the SC connector is still widely used, especially in GPON and EPON networks.

Its key features are:

- Ferrule size and material: 2.5 mm, ceramic

- Interface standard: IEC 61754-4

- Mating cycles: 1000

The SC fiber connector might not be the most sophisticated or innovative connector design, but its reliability and simplicity ensure that it stays among the most widely used connectors out there.

Want to know more about our fiber optic repair expertise?

Contact us!Fiber Connector Type #3: FC Fiber Connector

While the FC fiber connector is not so widely used nowadays, it still deserves a mention.

Just like the SC connector, it was one of the first fiber-optic connectors that emerged together with the fiber-optic technology and the first connector design to utilize a ceramic ferrule.

The most distinctive design feature of the FC fiber connector is its stainless-steel screw-type coupling.

This type of coupling is more secure and rigid compared to snap latches found in LC and SC connectors. FC fiber connectors are commonly used in stressful, high-vibration environments, both indoors and outdoors.

However, the design of the FC connector leads to two inherent drawbacks: inflated cost due to the expensive nickel plating used in the coupling and the bulkiness that makes the FC challenging to fit into compact wiring arrangements.

The features of the FC fiber connector include:

- Ferrule size and material: 2.5 mm, ceramic

- Interface standard: IEC 61754-13

- Mating cycles: 500

The FC connector is not as advanced in terms of design and performance as some more modern variants – including those that also feature a screw coupling. However, its reliability and rigidity keep finding applications in demanding use scenarios.

Fiber Connector Type #4: ST Fiber Connector

The ST or Straight Tip optical cable connector was developed by AT&T to compete with the FC connector.

As such, the two are similar in terms of design and specification. However, the ST connector features a spring-loaded twist-locking bayonet coupling, as compared to the FC’s archaic screw lock.

Because of that, ST connectors are easy to use, as they can be connected and disconnected quickly. This made them quite common in busy networks, such as college campuses, corporate headquarters and military objects.

The ST connector shares most of its key specs with the FC connector, except for the interface standard:

- Ferrule size and material: 2.5 mm, ceramic

- Interface standard: IEC 61754-2

- Mating cycles: 500

Just like the FC connector, the Straight Tip has become a rare sight due to its excessive cost and complexity. Its use has steadily declined since the 1990s, in favor of the more cost-effective LC and SC connectors.

Fiber Connector Type #5: MTP Fiber Connector

The MTP fiber connector is quite different from the connectors mentioned on this list thus far.

To begin with, it does not feature a ceramic ferrule. Instead, it has a molded plastic port that can be connected and disconnected as easily as a USB cable.

Another key difference is the capacity – a single MTP connector can have as many as 24 strands of fiber attached to it, and each one can feature a different connector on the other end.

The MTP connectors are most frequently found in data centers where they are used to interconnect equipment and on the supplier side of a fiber optic network.

Still, MTP connectors are becoming more common in consumer solutions thanks to their low cost and versatility.

The key characteristics of the MTP connector are:

- Ferrule size and material: 2.5×6.4 mm, molded plastic

- Interface standard: IEC-61754-7

- Mating cycles: 1000

The MTP connector is more function than form, as its bulky size makes it tricky to fit into smaller optic fiber arrangements.

However, it makes up for this drawback with its low cost and the opportunity for it to be used as a splitter of sorts, sending the optic fiber signal to different devices.

Need to talk to an expert?

Get in touch!Fiber Connector Type #6: E2000 Connector

Developed by Switzerland-based company Diamond SA to be the finest fiber optic connector money can buy, the E2000 is quite unlike any other fiber optic connector type on the market.

It features a full set of innovations that separate it from the competition, such as:

- A spring-loaded shutter that shields the ferrule when the connector is not in use

- Diamond’s proprietary Active Core Alignment (ACA) process that helps align the fiber core with the center of the ferrule

- A unibody ferrule made of a custom composite material that includes zirconia and titanium

All these innovations result in the E2000 offering as many as 1,000 mating cycles and an industry-unmatched insertion loss of only 0.1 decibels.

By comparison, the average insertion loss in most other types of connectors is between 0.25 and 0.5 dB.

Naturally, the E2000 connector also has an obvious downside – the prohibitive cost, especially when compared to other fiber optic connector types.

Fiber Connector Type #7: CS Connector

The CS connector was introduced in 2018 by Senco Corporation and designed specifically with the next-gen connectivity solutions such as edge computing and Internet of Things in mind.

The CS is a duplex connector – which means that it features a set of two independent 1.25 mm LC connector ferrules, each connected to an independent optic fiber strand.

This high-density design means that the CS connector can be integrated into sophisticated network setups that are required to support the 400 Gigabit Ethernet connectivity – the main intended application of the CS.

Since the CS connector is a recent technology, it is not yet known just how reliable it is, especially compared to older types of connectors.

As such, any fiber optic cable cuts or potential repairs of any fiber optic network would require the input of qualified specialists.

Luckily, the experts at Commercial Electronics Inc. are fluent in the latest fiber optic technology, providing fiber optic repair services for all kinds of fiber optic networks.

Explore more of our fiber optic solutions

Check our solutions!